6-Pin vs. 7-Pin Lock Cylinders

6-Pin vs. 7-Pin Lock Cylinders

Understanding Real Security Differences

Why “7-Pin” Does Not Always Mean Higher Security

In today’s lock cylinder market, many products are promoted as “7-pin cylinders”, often implying better security than standard 6-pin designs.

However, not all 7-pin cylinders are created equal.

Some products labeled as “7-pin” do not actually have seven functional pin stacks. Instead, they are based on a traditional 6-pin structure with an additional, non-working pin hole added for appearance.

This page explains the real structural differences and helps you identify what truly improves security.

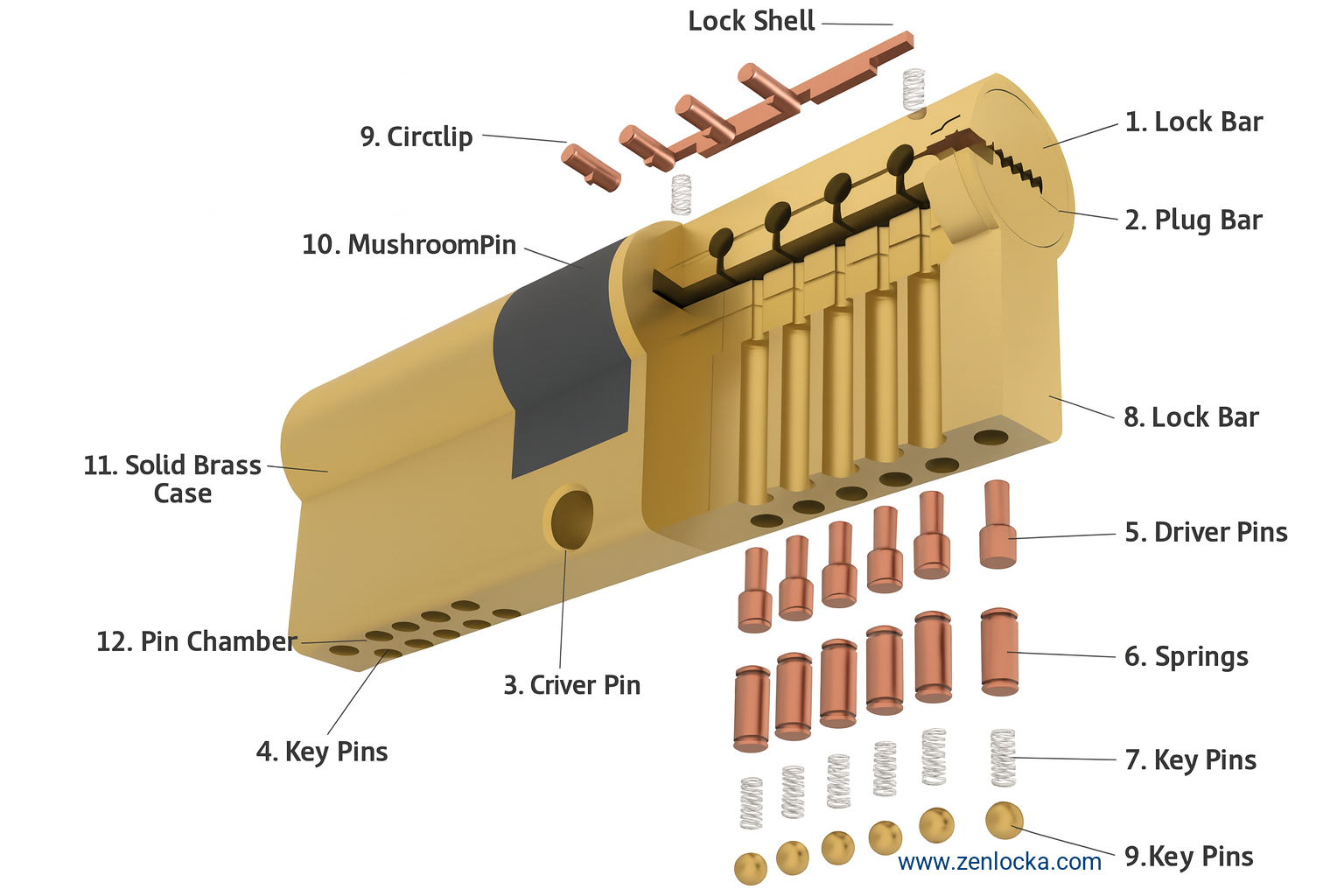

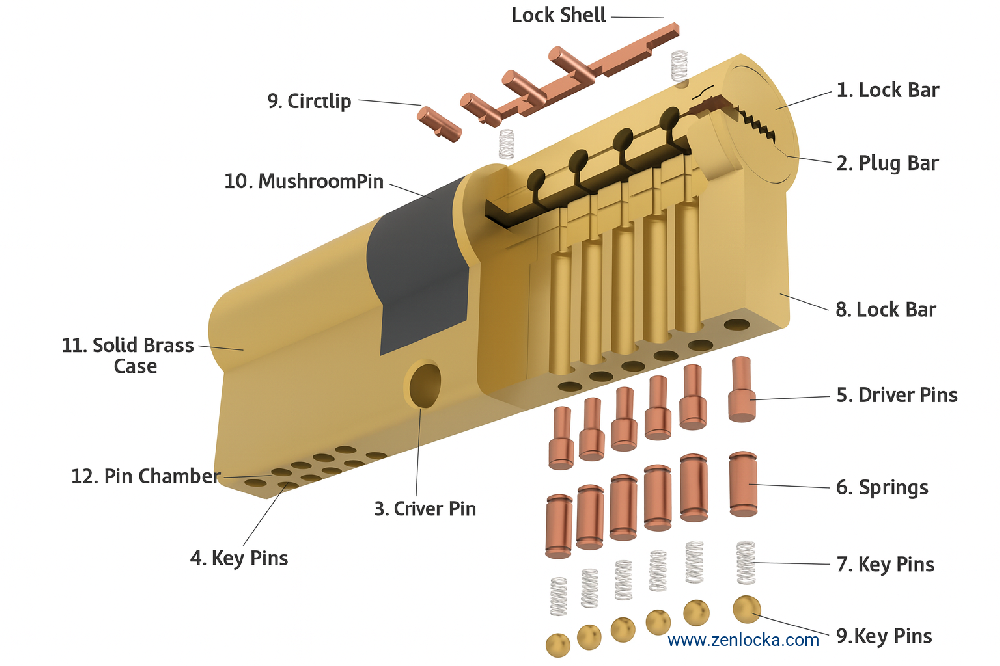

How a Pin Tumbler Lock Works

A pin tumbler lock operates based on the alignment of pin stacks at the shear line.

When the correct key is inserted:

Each bottom pin (key pin) is lifted to a precise height

The separation between top and bottom pins aligns exactly at the shear line

Only then can the plug rotate and unlock

👉 Every functional pin stack increases security by adding more combinations and resistance to manipulation.

Standard 6-Pin Lock Cylinder

Key characteristics

6 functional pin stacks

All pins actively control the shear line

6 effective key cuts

Security level

Stable and widely used

Moderate resistance to picking

No misleading structure

This is the industry baseline for mechanical cylinders.

Genuine 7-Pin Lock Cylinder (All Pins Functional)

A true 7-pin cylinder is a structural upgrade, not a cosmetic one.

What makes it genuine

7 pin stacks positioned within the plug’s rotation path

All 7 pins must align at the shear line

7 effective and functional key cuts

Security advantages

Significantly increased key combinations

Higher resistance to picking and decoding

Real improvement over 6-pin designs

✔ This is what “7-pin security” is supposed to mean.

Common “Fake” 7-Pin Cylinders on the Market

Some cylinders marketed as “7-pin” are manufactured by:

Taking a standard 6-pin cylinder

Drilling an extra pin chamber

Adding a decorative or inactive seventh pin

Typical signs

The 7th pin does not intersect the shear line

Lock operates normally even if the 7th pin is removed

The 7th key cut has little or no functional effect

❗ In practice, these locks still operate as 6-pin cylinders.

Security Comparison at a Glance

| Feature | 6-Pin Cylinder | Genuine 7-Pin | “Fake” 7-Pin |

|---|---|---|---|

| Functional pin stacks | 6 | 7 | 6 |

| Effective key cuts | 6 | 7 | 6 (7 visually) |

| Key combinations | Medium | High | Medium |

| Picking resistance | Medium | High | Medium |

| Structural honesty | ✔ | ✔ | ✖ |

How to Identify a Real 7-Pin Cylinder

For distributors and professional buyers:

Check the structure: Does the 7th pin intersect the shear line?

Examine the key: Are all cuts functionally different?

Read specifications carefully: Look for “7 functional pin stacks”

Be cautious of vague terms like “7-pin design” without clarification

Our Position on Security Design

We believe that security should be based on real structure, not marketing numbers.

A genuine 7-pin cylinder provides measurable security benefits.

A non-functional pin does not.

That’s why we clearly distinguish between:

Number of pin holes

Number of functional pin stacks

Because true security comes from how the lock works, not how it looks.

Want to Learn More?

Contact us for detailed technical drawings

Request distributor training materials

Ask about our verified 7-pin cylinder designs

6-Pin vs. 7-Pin Lock Cylinders

6-Pin vs. 7-Pin Lock Cylinders

Technological Innovation Drives Industry Upgrades

Technological Innovation Drives Industry Upgrades

Keeping Pace with the Times, Creating the Future Together

Keeping Pace with the Times, Creating the Future Together

How to Choose Traditional Door Locks? Common Questions Answered | 2025 Hardware Door Lock Buying Guide

How to Choose Traditional Door Locks? Common Questions Answered | 2025 Hardware Door Lock Buying Guide

How to correctly choose hardware components?

How to correctly choose hardware components?